Posted at 12/08/2022 By : deep drawing Categories : Blog,Industry Comment: Comments Off on Metal stamping continuous die layout technology 1. Design principles of continuous stamping layout drawing

Before blanking of flat blanking parts (including flat blanks of various forming stamping parts – the same below), in order to save materials, economical and reasonable arrangement is carried out on plates, strips, strips and coils to obtain the best samples and achieve the best possible results. Possible high material utilization. In the cold stamping process design and die design, this is an important and technical work; in the cold stamping die structure design, the stamping part drawing, stamping process and its sample drawing are the main basis.

In the known professional publications, the layout of single-station blanking dies and composite die-stamping parts is introduced in detail, and the layout of multi-station continuous die-stamping parts is not involved.

The layout drawing of multi-station continuous stamping parts should fully explain the stamping process and the sequence of stamping steps, and indicate the feeding distance, the specific data of edge extension and edge overlap, the feeding method between stations, and all stamping processes and deformations of stamping parts. and separation process.

Die selection, structural design, stamping material utilization η, stamping productivity are closely related to the production cost of stamping parts, but also affect the quality of stamping parts and die life. The layout should fully consider the material supply and the production conditions of the stamping equipment. On the basis of ensuring the stamping quality, efforts should be made to make the stamping die have better structure, better operational safety and die technology, and comprehensively analyze the various factors that affect the layout. Factors, compare multiple schemes, and choose the best layout.

Before the die stamping design begins, the die stamping drawing and layout drawing should be analyzed to understand its main technical requirements and stamping difficulties, and lay the foundation for the die stamping structure design according to the rationality of the die stamping process and possible problems.

Among the many single-process dies, only blanking dies and single-station composite dies need to design layout drawings. That is to say, when blanking (blanking) flat blanks and forming stampings to develop flat blanks, nesting is required. And most of them are conventional nesting methods with scrap blanking along the edge, and most of them can only achieve less scrap blanking. Regardless of the layout method used, the rationality and advantages and disadvantages of layout are generally measured by the material utilization rate.

The layout of continuous die-stamped parts is different from the above. Material utilization η is not the most important and only criterion for measuring the quality of nesting.

For the layout of continuous die stamping parts, it is necessary to analyze the stamping process, reasonably design the stamping process and the sequence of the stamping process, fully consider the characteristics of the continuous stamping process and the needs of the stamping structure design, and pay attention to the feeding and inter-station feeding methods. selection and design of positioning systems.

Therefore, the layout of continuous die stamping parts is based on the design of continuous stamping process steps, with the core of ensuring the quality of stamping parts and the accuracy of size and shape, and the sequence arrangement of stamping steps and the selection of the feeding method between stations are as follows: Pilot, for the purpose of die selection and structural design, the basic principles that should be followed are as follows:

(1) It is beneficial to choose a simpler type and structure of punching die, and its operation is safe and the quality of punching parts is good.

(2) The manufacturing process of the die is good, the grinding is convenient, the molding cycle is short, and the cost of molding and repairing is low.

(3) The plate utilization rate η value is high.

(4) The mold life is longer.

(5) The stamping efficiency is higher, and the production cost of stamping parts is lower.

Among the above five articles, article (1) is the primary one.

Sometimes it is impossible to have both, the user’s requirements and delivery time should be considered first, and other terms can be appropriately relaxed. In many cases, higher material utilization η tends to complicate the structure of the die, making the die more difficult, and even difficult to manufacture with the existing die-making equipment and technical level, no matter how good the layout and the higher the η value. , and must also be abandoned; some would rather reduce the utilization rate of the plate η to obtain better molding processability, shorter molding cycle, and higher mold life.

2. Selection of layout form and its relationship with die type and structure

For blanking dies and composite dies with only one station, the layout methods of flat blanking and various forming blanks on plates, strips, strips and coils are usually: single row, straight row, Single row oblique row; double row parallel row, double row head-to-head row, double row head-to-head oblique row; multi-row row, staggered row and mixed row, etc.

Different nesting methods obtain different material utilization rates, and the choice of different nesting methods should first consider the size and shape accuracy of the punching parts, and then decide to choose the appropriate type of punching die and its structure.

If the dimensional accuracy of punched parts is required to be above 1t10 level, the layout method with edge and overlap should be adopted; the dimensional accuracy of punched parts without overlap layout is poor, generally below 1t12 level, or even as low as 1t14 level. If the dimensional accuracy of the punching piece is as high as 1t9 or higher and the punching piece is required to be straight, a punching die with a sliding guide column die set with a spring-loaded stripper structure should be selected, and its layout should be given enough edge and overlap.

According to the German Industrial Standard din1543, the cold stamping steel plate is classified according to the thickness t: t<3mm is a thin plate.

In the production of products in the instrumentation and electronic industries, ultra-thin foil stamping parts with t≤0.3~0.1mm or even ≤0.1~0.05mm are often used, which brings many difficulties to stamping layout and die design.

Because the edge of the nesting, the width of the overlapping edge and the size of the blanking gap all increase or decrease with the thickness t of the blanking material.

When t≤0.5mm, the width of the lap and edge should be greater than t so as not to be pulled into the die hole during punching, and to make it have sufficient strength and ensure that the lap frame has a good feeding rigidity; t= 0.3mm low carbon steel plate, according to the class I gap stipulated by gb/t16743-1997 “Blanking Gap” Internationally, 3%t can be taken as the unilateral gap of punching die c=3%×0.3mm=0.009mm, t=0.1mm then c=0.003mm, which is 3μm. And gb/t2854-90 international grade I sliding guide guide column die set stipulates the guide column guide sleeve matching clearance is 0.010 ~ 0.016mm. Therefore, when the above-mentioned ultra-thin material is punched and continuously punched, special attention should be paid to selecting a suitable layout method and designing a reasonable and precise mold structure, otherwise it will be difficult to complete the punching of such punching parts, and it is impossible to meet the requirements. Dimensional and geometric accuracy.

For continuous stamping and forming of ultra-thin punching parts with t<0.5mm, the width of the overlapping edge and the edge of the layout can be the same, and it can be appropriately enlarged according to the needs of the die structure design. In terms of the selection of die structure type, it is recommended to select the guide column die frame elastic pressure unloading guide die, and it is best to install the elastic pressure guide plate on the guide column and install a small guide column on the discharge plate (guide plate) to ensure the elastic pressure discharge. The guide plate type punching die has precise guidance and improves the punching accuracy of the punching die; the coaxiality and position of the punching group holes put forward higher requirements on the accuracy of the layout and feeding distance and the feeding and positioning of the punching die. Special attention should be given to layout.

Ultra-thin punching parts with material thickness t≤0.1mm, especially complex-shaped punching parts formed by multiple stations and one die, should not use multiple rows of oblique rows, facing rows and turning punches, and it is even more unsuitable to use mixed rows. Otherwise, the frame will be easily deformed, broken, or even pulled into the die during feeding, which will affect production, increase scrap products, and damage the mold; for medium and heavy plate punching with a material thickness of t≥3mm, cutting and stacking layout is not recommended. , t ≥ 4.75mm, it is not recommended to use nesting and cutting layout. Otherwise, it will bring difficulties to the structural design of the mold.

For high-precision foil stampings with dimensional accuracy ≤±0.01mm and material thickness t≤0.1mm, especially for stampings with complex shapes with a precision higher than 1t9, it is recommended to use a ball-guide-pillar die-base elastic-pressure unloading guide-type die structure.

Layout drawing design points The layout drawing design of single-station blanking die and compound die is to expand the shape of flat blank according to flat blanking parts and three-dimensional forming parts, and repeatedly arrange them on strips and strips to ensure the quality of punching parts. In the case of production efficiency and process requirements, the die structure is simpler, the mold making is more convenient, and the highest possible material utilization rate is the criterion, and a better layout method is selected. Under normal circumstances, the shape and size structure of the blanking parts determine the type of layout, and most of them need to use the traditional layout method with edge and overlap to carry out blanking with waste.

According to many years of practical experience, for the design of the layout drawing of single-process blanking and composite punching and single-station integrated composite stamping, it can be considered as a single blanking of flat blanks and three-dimensional forming parts. Compared with single punching die, the layout of continuous die punching parts is much more complicated. The layout should ensure the smooth implementation of the continuous punching process and obtain the highest possible η value. The operation is safe, the efficiency is high, there are many influencing factors, and the requirements are high. The steps and key points are as follows:

(1) After a detailed process analysis of the stamping parts, the feasibility of continuous stamping and one-die forming of the stamping parts is studied, and a number of stamping process schemes are proposed for comparison, and the layout is implemented after selecting the best ones.

(2) The shape, size and accuracy of the stamping directly affect the continuous stamping process and the sequence of the steps. When laying out the layout, the manufacturability of the continuous stamping and the needs of the die structure design should be considered, and attention should be paid to the sequence of the steps and the arrangement of the stations. The following points:

a. The holes in the group of holes on the punching piece whose hole spacing accuracy is required to be above 1t10 or the hole spacing tolerance value is less than 0.01mm should be punched out in one or two adjacent stations;

b. If the hole wall and hole edge of the punched part are smaller than the material thickness t or less than 2mm, they should be punched out in two stations in steps to enhance the strength of the die and expand the installation position of the punch on its fixing plate;

c. For the coaxiality and position of the group holes, the requirements are very high, and the tolerance is less than 0.01mm. The relevant holes can be punched out at one time or in two adjacent stations. The parts that require smooth punching and punching should be concentrated. Implemented at one or two stations;

d. If the shape of the punched part and the size tolerance of the formed part are very strict, the overall blanking can be considered and then bent or deep drawn; if the size of the local boss or notch of the punched part is strict, it can be punched separately by multiple stations. post splicing;

e. For small and complex shaped stampings with large output, multi-station continuous stamping and one die should be used as much as possible to improve the quality and efficiency of stampings;

f. The dimensional accuracy requires high-precision punching parts above 1t10. When laying out samples, the number of steps should be minimized to prevent the number of stations from being too large, the accumulation of feeding errors will be large, and the punching accuracy will be reduced. Partial fine punching, upsetting extrusion, flattening, etc. should be Arrange special work stations;

h. For punching parts with complex multi-directional bending, lateral punching and incision that need to be punched with lateral force, consideration should be given to using wedge drive transverse punching to form after plane punching, incision or before blanking. Precision and Efficiency.

(3) Considering the requirements of the die structure design and the required position of the stamping deformation, set up the necessary neutral station, and increase the installation position of the punch on the fixed plate; Surface area, an empty station should also be added to increase the wall thickness of the die.

3. Layout type and method of continuous die stamping

According to the characteristics of the continuous die stamping process, the same feeding method of the station, whether the layout has overlapped edges, and the method of removing process waste, the layout of the continuous die stamping parts can be summarized into the following types and layout methods:

1. Slitting and combining layout

Each station punches and forms a part of the punching piece respectively. Each station is relatively independent and independent of each other. Its relative position is controlled by the die, and finally combined into a complete and qualified punching piece, see Figure 1a), b), f), j).

2. Piece and cut combination layout

The inner hole and shape of the punching piece, even a complete blanking line of any shape, are punched separately by several stations, and finally assembled into a complete punching piece. Although it is similar to the slitting combination, it is not the same. The combination of each station and the cutting edges are related to each other, and the interface parts must overlap, which increases the difficulty of mold making.

3. Cutting edge layout

The complex shape of the side of the punched piece is obtained by the method of punching along the edge, that is, the cutting edge layout. When the length l of the punching edge in the feeding direction is equal to the feeding distance s, that is, l=s, the punch can replace the side edge and undertake the task of cutting the edge of the fed raw material. This type of side punch is commonly referred to as a forming side edge. Because jb/t-76481-94 has few standard side edge varieties and limited size specifications, the maximum cutting edge length is only 40.2mm. When the feeding distance s>40.2mm, only non-standard side edges can be used.

Another disadvantage of using a standard side edge is that it is necessary to cut a certain width of material on the side of the raw material to form an incision with a length equal to the feeding distance. Positioning the feeding raw material increases the process waste and reduces the η value by 2% to 3%. %. Using the side punch to cut the edge can not only complete the blanking of any complex shape of the side profile of the punching piece, but also realize the limit of the feeding distance of the raw material, instead of the standard side edge, which serves multiple purposes.

4. Cut and overlap the layout

For slender and thin blanking parts, long blanking parts with complex contours to be blanked at the part connected to the lap edge, can obtain high-quality and high-yield effects by laying out the lap edge, which can avoid slender blanking parts Disadvantages such as distortion and difficult unloading. The more typical punching parts are instrument hands, watch second hands, etc. The above cutting edge layout is used, and the effect is very good. For the convenience of molding, sometimes the edge is enlarged to facilitate blanking, and the edge is left on the raw material as a punch. The pieces are finally cut and separated.

5. Combined punching and nesting along edge and overlapping edge

Step by step punching the edge and lap by sub-station, to obtain the layout of the formed punching blank and punching and forming, which is called the combined punching layout of the edge and the lap. The process wastes are washed away at each station, and the punched parts are left on the raw materials and gradually formed until the final station is separated. This type of layout can keep the stations on the same plane and arrange them in a straight line along the feeding direction. The raw materials are used to carry the workpieces into place between the stations. The mold structure is simple, and the operation is convenient and safe.

6. Nesting layout

Use the structural waste of the inner hole of the large-sized punching piece to punch the smaller-sized punching piece of the same material in the special station of the same set of continuous molds, that is, the nesting layout.

Under normal circumstances, the small-sized punching parts in the inner hole are punched first, and the large-sized punching parts are often punched out at the last station.

The nesting of gaskets with a single-station composite blanking die is a typical nesting layout that has been known for a long time. For the nesting layout of multi-station continuous blanking parts, because the upper and lower stations have no overlapping edges, the coaxiality is required to be high, and the feeding distance must be small to ensure the size and shape accuracy of the nesting blanking parts.

7. Layout layout

Using the process waste of the punched parts and the structural waste connected along the edge, the punching parts of the same material are spliced and punched together, that is, the layout is cut out. The difference from nesting and layout is that stenciling is to make the best use of process waste or excess edge and overlap, as well as the outer edge structure waste generated due to the complex shape of the punched parts and the large difference between convex and concave. The punching material is the same. Various punching pieces. When laying out samples, make full use of the convex and concave parts of the shape of the punching parts, and insert forks into each other to make full use of the raw materials.

No lap layout and no-waste blanking Since most of the continuous die-stamping parts use edge and lap layout, only blanking with waste can be carried out. If the layout without edge and edge can be carried out, and the blanking part has no structural waste, it can be blanked without waste. Completely scrap-free blankings that truly achieve 100% or near 100% sheet utilization are rare. Any punching that can be used for layout without overlapping can be punched with less waste.

In order to implement the blanking of blanking parts with no waste and less waste, it is first necessary to carry out the layout of blanking parts without overlapping edges.

There are certain conditions and methods for the implementation of no-overlap nesting. In addition to the above-mentioned continuous die-punching parts, which can be used for layout without overlapping edges and blanking with no waste or less waste, single-process punching dies and single-station composite punching dies can also do the same.

4. Non-linear feeding continuous composite die-stamping method

The feeding direction of most continuous molds is carried out along a straight line on the same plane, and the feeding of each station is carried out by feeding raw materials. For this reason, the punched parts are always kept on the raw materials with lap edges for stamping processing at each station. The finished punching piece connected with the lap edge cannot be separated from the raw material until the processing is completed to the last station. For some punching parts with large flange heights, large drawing heights and complex shapes that require multi-directional force bending, it is often necessary to blank them as a whole and then form them on another set of punching dies.

Otherwise, the punched part can be taken out from the die cavity because the die needs to have a large opening height. If the conventional continuous die is used to arrange the stations in a straight line on the same plane along the feeding direction, it will be difficult to design the die structure.

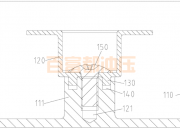

This type of punching piece is formed by a multi-station continuous die, and its layout method is completely different from the above-mentioned conventional continuous die layout. The blanking blank is pushed to the forming station at a certain angle to the feeding direction of the raw material, and is bent or deep drawn. Make the stations of the die arranged in an L shape, and the stations are not on the same plane

With the rapid development of modern stamping technology, the continuous improvement of stamping mechanization and automation, and the improvement of stamping safety production requirements, continuous dies of this type of structure will be increasingly widely used.

The three-station continuous composite die for lifting ring punching parts, the first station punches rectangular holes, the second station is blanking, bending and compound punching, and the third station is a feeding system driven by the wedge of piece 8. After the curved workpiece at the second station is pushed into place along the bending core piece 12, the two sets of 13 cam drive mechanisms are used to exert force opposite and perpendicular to the feeding direction to push a pair of forming die pieces 17, and the stamping workpiece is finally formed. The die has both the action characteristics of a continuous die and the function of a composite die. Since the second to third stations are formed by separating the workpiece from the raw material, it is not realistic to call the progressive die;

Calling a continuous die ignores the function of the second station compound stamping and the separation and deformation of the entire die and the characteristics of the compound stamping, so it is more appropriate to name it a continuous compound die.

The continuous composite die adopts staggered double rows and straight rows. After the overall blanking, the unrolled blanks are pushed to both sides and bent at the third station. The production efficiency is high and the punching quality is good. This type of automatic or semi-automatic continuous compound die is safe to operate, and will be used more and more with the diversification of coil supply varieties and specifications.

Read More →