Custom Precision deep draw manufacturing

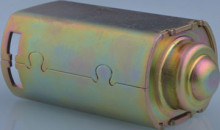

Custom Metal stamping, Deep Drawn Metal Enclosures, motor housing, sensor housing, DC motor case, solenoid housing, progressive die stamping

Balford Corporate

Zhejiang Balford Mechatronics Co.,Ltd. was established in 2016, located in Huzhou City, where is called ‘The Capital of Metal Hardware’. We focused on difficult stamping and deep-drawn technologies. The main products are DC motor housing, motor cover, motor case, motor can, metal stamping, punching, pressing and difficulty custom deep drawn stamping products….China Balford Manufacturing services food, aviation, medical, automotive, electronics, aerospace industries, and many more with custom and standard ZERO style deep drawn metal parts, boxes, cases, cups,caps, canisters, instrument housings

Latest News

Stamping Die

Stamping Die06/01/2023

stamping die is special processing equipment for processing materials. Metal or non-metal 41. Finished part&# 40. …

What Is Deep-Drawing Stamping

What Is Deep-Drawing Stamping06/01/2023

deep drawing is a metal stamping process, which is used to make metal …

Characteristics of metal stamping parts

Characteristics of metal stamping parts05/01/2023

Metal stamping parts are widely used in life and are one of the most common metal …

Continuous die stamping

Continuous die stamping04/01/2023

Continuous die stamping is characterized by high batch production efficiency, easy automation, safe operation, long die …

Metal Spring Clip

Metal Spring Clip03/01/2023

Metal spring clips are usually made of stainless steel or manganese alloy after heat treatment and are important …

Introduction to multiple drawing

Introduction to multiple drawing02/01/2023

As we all know, when drawing, stamping and drawing products sometimes need to go through multiple …

What Is a Stamping Die?

What Is a Stamping Die?01/01/2023

stamping is a cold forming operation, which means that no heat is intentionally introduced into the …

Metal Stamping Cost Reduction

Metal Stamping Cost Reduction31/12/2022

The rational production of metal stamping parts is to reduce development costs, improve material utilization, reduce …

30/12/2022

Chip jumping of metal stamping die refers to the phenomenon that the sheet metal jumps to …

Stamping Die Components

Stamping Die Components25/12/2022

stamping die is usually composed of fixed die and movable die. The fastener is fixed to …

Types of Deep Drawing Processing

Types of Deep Drawing Processing23/12/2022

Generally speaking, a metal stamping manufacturer will divide the deep drawing process into …

How Can Metal Stamping Use in The Medical

How Can Metal Stamping Use in The Medical22/12/2022

With the rapid development of the medical technology sector, medical equipment is crucial to the modern medical care …

Top 6 Benefits of Metal Stamping

Top 6 Benefits of Metal Stamping21/12/2022

For decades, with the continuous development of technology, more and more industries have been closely related to metal …

Differences between deep drawing and metal stamping

Differences between deep drawing and metal stamping20/12/2022

With the development of metal processing technology, it is very important to choose the right process to manufacture …