Answer for how to make a metal enclosure using deep drawing process?

how to make a metal enclosure using deep drawing process

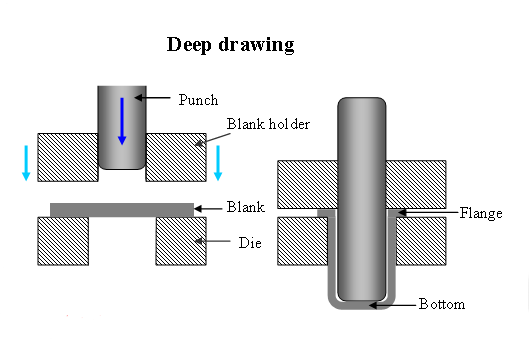

deep drawing is a cold metal forming process, in which a flat and round metal blank is forced into a die cavity by hydraulically press driven punch.

A enclosure-like cylindrical part, having the depth greater than its diameter, is formed as a result of deep drawing.

The process is following in the picture:

Typical stages of a deep drawing process are as follows:

shearing a blank (round rectangular or other shape);

clamping the blank on the die;

stretching the blank by the punch forcing it into the die cavity;

returning the punch and removal the part from the die;

trimming the excess blank.

The maximum amount of deformation occurs in the enclosure walls, deformation of the flange is lower, bottom region undergoes no deformation.

deep drawing alloys should possess high ductility in order to withstand large amounts of deformation.

motor cases, beverage cans, motor housing, motor cap, motor cover, motor shell and other cup-like parts are manufactured by deep drawing process.